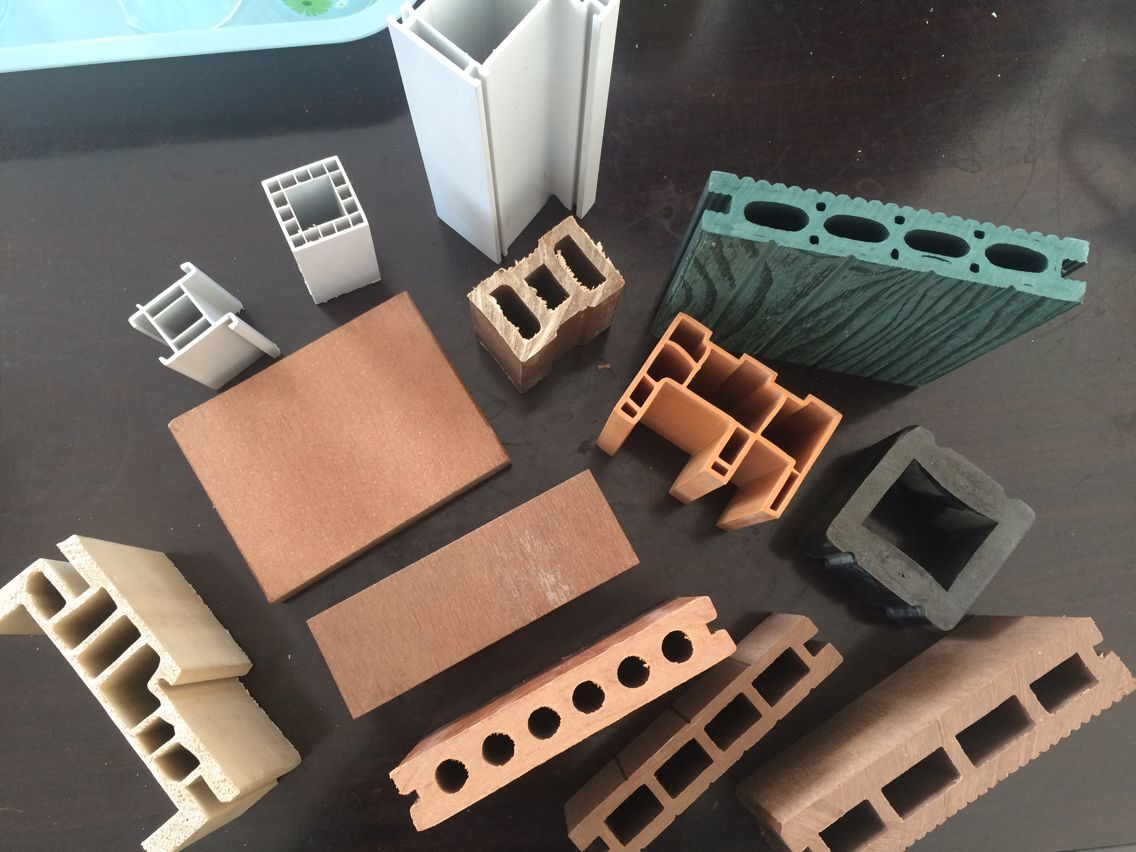

The line uses raw plastic material or

recycled plastics (PVC, PE, PP) and wood fiber (wood powder and other plant

fiber such as rice bran, straw, etc.) as the main raw material (the two

accounted for more than 90%) the production of an industrial - wood plastic

composites (WPC).

The product has the following advantages:

1. Wood-plastic composite materials instead of full-wood products, protecting

forest resources.

2. Wood-plastic composites can use the stalks of plants, reducing environmental

pollution

3. Wood-plastic composite material to eliminate white pollution, cleaning up

the natural environment

Applications:

The production line of products can be used for the production of building

templates, building blocks toys with plates, trays, boxes, pallets and other

packaging equipment; the end of plank, sleepers and other storage supplies,

outdoor flooring, railing, outdoor chairs, garden supplies; outdoor flooring,

sun rooms, signage, flow box, stadium chairs, and other load-bearing beam.

|

Name of |

Spec./Model |

YF210 |

YF240 |

YF500 |

YF800 |

|

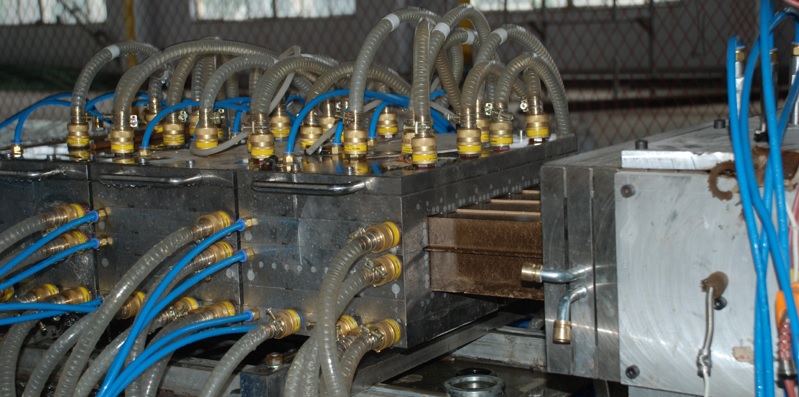

Extruder |

Extruder model |

SJSZ55/110 |

SJSZ65/132 |

SJSZ80/156 |

SJSZ92/188 |

|

Dimension(m) |

3.3*1.45*2.1 |

3.45*1.45*2.25 |

5*1.54*2.28 |

6.2*1.55*2.7 |

|

|

Capacity(kg/h) |

50-150 |

80-250 |

100-350 |

200-600 |

|

|

Installed power(KW) |

25 |

64 |

115 |

168 |

|

|

Sizing table |

Dimension(m) |

4.2*1*1.1 |

5.8*1.*1.1 |

6.5*1.5*1.1 |

6.5*1.5*1.1 |

|

Installed power(KW) |

18 |

24 |

30 |

43 |

|

|

Hauling and cutting machine |

Dimension(m) |

5.8*1.1*1.7 |

5.8*1.1*1.7 |

3.1*1.3*1.7 |

3.55*1.85*1.6 |

|

Hauling speed (m/min) |

0-4 |

0-4 |

0-3 |

0-2 |

|

|

Hauling force (N) |

30000 |

30000 |

35000 |

50000 |

|

|

Max cutting area and width (mm) |

240*65 |

240*65 |

500*80 |

800*80 |

|

|

Installed power (KW) |

6 |

6 |

8 |

8 |

|

|

Stacker |

Stacking length(mm) |

6 |

6 |

6 |

6 |