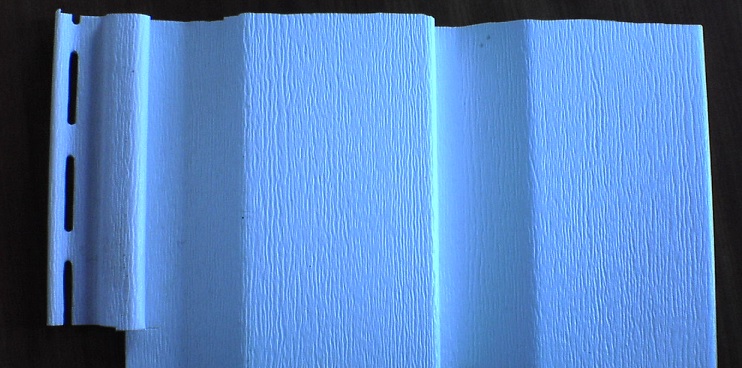

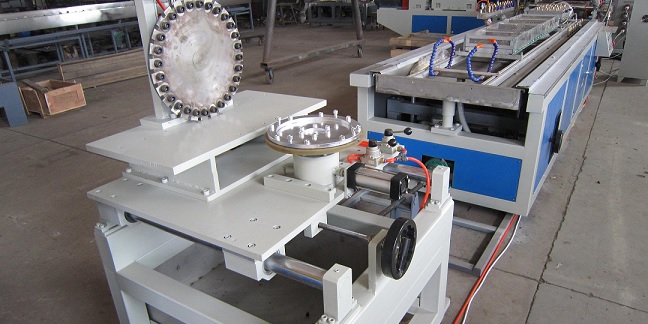

YF series PVC Siding and Ceiling extrusion line is mainly used for extrusion of PVC siding panel and ceiling panel profile, electrical conduit trucking channel, decorating profile etc. The whole production line includes conical twin screw extruder, die head, vacuum calibrating table, haul off unit, cutting unit, film sticking device, and stacker. According to the different profile section and mould design, varied models of twin screw extruder and downstream equipments can be optional.

Performance and advantages:

1.Extruder: adopting specially screw designs according to different materials

make the high polymer micro-foam uniform plasticization, high extrusion.

Imported famous brands AC inverter makes the rotation speed stable to ensure

the main extruder and accessory machines move synchronously.

2.Vacuum calibrating table: adopts powerful turbo cooling system, easy to

achieve satisfactory cooling effect. According to different moulds and

different customer requirements, the vacuum calibrating table can be optional

as 4m, 6m.

3.Haul off machine: adopts special lifting technology, and has the features of

stable running, reliable working, powerful hauling etc,

4.Cutting machine: the moving speed of the cutting unit is synchronized with

hauling speed. Through presenting, the cutting unit is capable for automatic

cutting with fixed length. Dust recycling device is also equipped.

|

Name of |

Spec./Model |

YF210 |

YF240 |

|

Extruder |

Extruder model |

SJSZ55/110 |

SJSZ65/132 |

|

Dimension(m) |

3.3*1.45*2.1 |

3.45*1.45*2.25 |

|

|

Capacity(kg/h) |

50-150 |

80-250 |

|

|

Installed power(KW) |

25 |

64 |

|

|

Sizing table |

Dimension(m) |

4.2*1*1.1 |

5.8*1.*1.1 |

|

Installed power(KW) |

18 |

24 |

|

|

Hauling and cutting machine |

Dimension(m) |

5.8*1.1*1.7 |

5.8*1.1*1.7 |

|

Hauling speed (m/min) |

0-4 |

0-4 |

|

|

Hauling force (N) |

30000 |

30000 |

|

|

Max cutting area and width (mm) |

240*65 |

240*65 |

|

|

Installed power (KW) |

6 |

6 |

|

|

Stacker |

Stacking length(mm) |

6 |

6 |