75-800 Double wall corrugated pipe characteristics: inner layer smooth, outer layer trapezoidal corrugated-size, hollow wall between inner layer and outer layer. Its unique structure makes the pipes posses the advantages of good ring stiffness, light weight, high pressure resistance, good toughness, corrosion resistance, wear resistance, and easy construction, low installation cost, long life and other characteristics. It is widely used in municipal renovation project, construction, industrial and agricultural drainage, agricultural irrigation, sewage treatment works and other fields. Is the best alternative to traditional cement pipe, cast iron pipe and other material pipes.

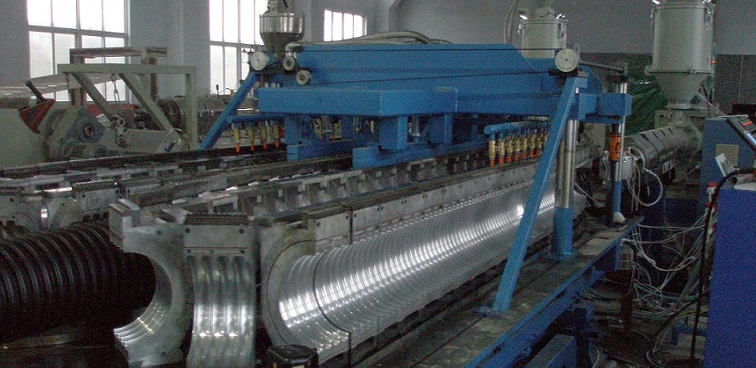

● Extruders: High efficient single screw extruder for PE conical twin screw extruder for PVC. The inner and outer layers of the corrugated pipe are independently feed material by two extruders. It can make the inner and outer layers produce different material and guarantee high efficiency extruding

●Die head: the extrusion die head has two channel structure, nitriding and polishing handling, special designed mouth molds, suitable for different material and different ring stiffness pipe production. The special mold structure assures the inner and outer layer wall thickness even and forming stability.

●Corrugation forming machine: It is horizontal structure with shuttle type transmission and the main part position can be adjusted, equipped with advanced water cooling system and vacuum forming system. It greatly increases the production speed. Special belling on line function decreases investment cost and improves production efficiency.

●Mold blocks: Blocks are made of special aluminum alloy material through precision casting with the advantage of light weight, high rigid degree, good abrasion proof, small heat-expanding ratio, and so on. The forming blocks can be cooled by air and water with a fast forming speed and cooling effective.

●Cutting machine: High-strength alloy steel blade, rotary cutting, smooth pipe incision, dustless cutting. The tracking device makes the cutting location precision. Germany SIEMENS professional PLC programmed controlling system makes operation easy and sensitive.

● Others: High quality accumulator can resist the power cut, and auxiliary battery makes operation table to move back when the power is cut.

Main technical data:

|

Model |

SBG-250 |

SBG-500 |

SBG-1000 |

|

Pipe size(mm) |

DN/ID 100-250 |

DN/ID200-250 |

DN/ID 200-800 |

|

Extruder |

SJ-65/33*2 |

SJ-65/33, |

SJ-75/33, |

|

Pipe die |

DN/ID |

DN/ID 150, |

DN/ID 200, |

|

Corrugator |

SBGC-250 |

SBGC-500 |

SBGC-1000 |

|

Spraying cooling tank |

SDP-250 |

SDP-500 |

SDP-1000 |

|

Cutting machine |

SQG-250 |

SQG-500 |

SQG-1000 |

|

Stacker |

SFL-250 |

SFL-500 |

SFL-1000 |

|

Capacity |

360 |

530 |

950 |

|

Total power |

310 |

360 |

540 |

|

Dimension |

28*4.5*2.8 |

31*4.5*3.8 |

32*4.8*5.2 |

|

Weight (t) |

27 |

38 |

56 |