1)

PET&PP

are using the recycling bottle flakes as raw materials by making them melt

directly

which can reduce 30% production cost.

2) According to PET molecular chain structure, the crystallizing drying system

is specially designed with uniformed drying. It can produce PET straps in

different specifications directly and doesn’t need to change the mould head.

Straps produced by this machine have high testile strength, not easy to

break.

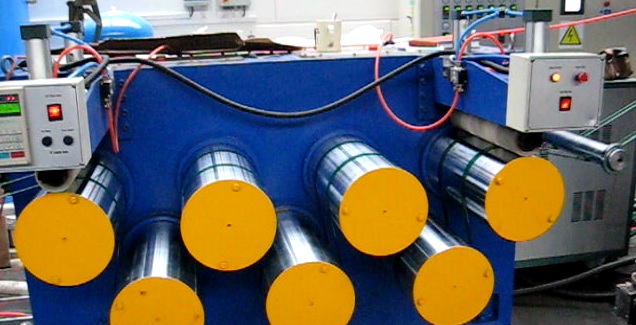

3) High efficient screw with long L/D, stable extrusion, uniformed

plasticization, accurate temperature control, high extrusion capacity.

4) Large area filtration device is installed, suitable for crushing materials.

It is also equipped with manual or automatic exchanger device.

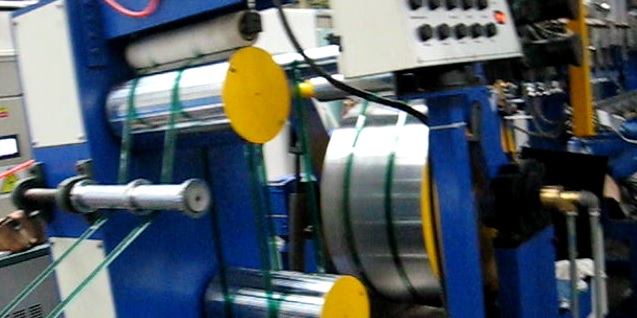

5) The stretching device with large hauling force and insulation calibrating

oven can guarantee the strap band good shape, not bend, unformed width and

bending degree and can reach automatic packing.

6) Large volume stainless steel water tank, liquid level can be controlled

automatically.

7) Low energy consumption, high production capability

Main technical parameters:

|

Model |

GES-65 |

GES-75 |

GES-90 |

|

Extruder |

65 |

75 |

90 |

|

Output |

60 |

90 |

120 |

|

Power |

59 |

74 |

92 |

|

Products size mm |

5-22 |

5-22 |

5-22 |