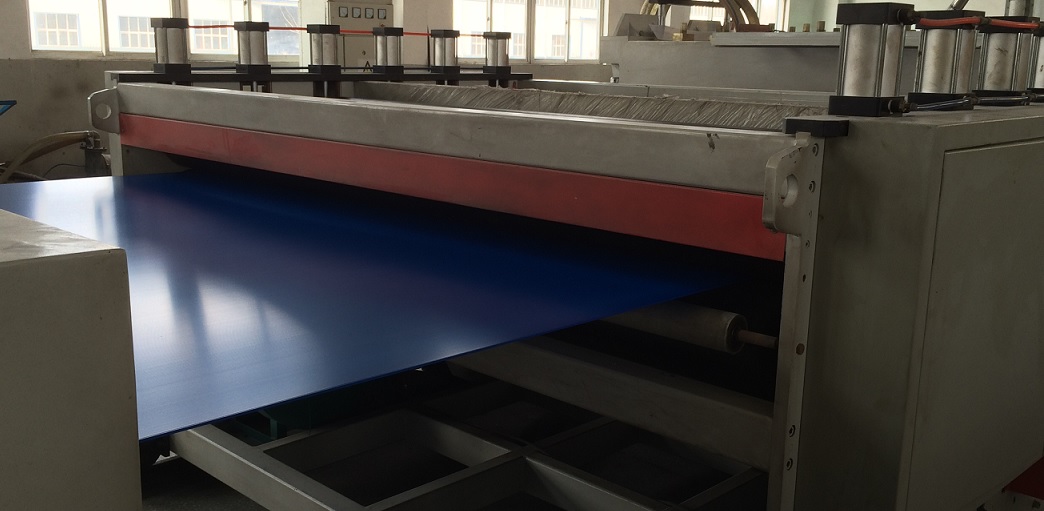

This extrusion line consists of

single screw extruder, melt-pump, hydraulic filter exchanging unit,

hollow

sheet die head, vacuum calibrating table, first haul off machine, oven, corona

treating unit, cooling table, second haul off machine, trimming and

length-settled cutting units and stacker etc.

Characteristics of vacuum calibrator:

1. High quality mould steel or high strength Al-Mg Alloy

2. Special harden treatment and non-sticky coating on the surface.

3. Independently controlled vacuumize device and temperature controlling

system.

4. Consist of vacuum sealing edge device.

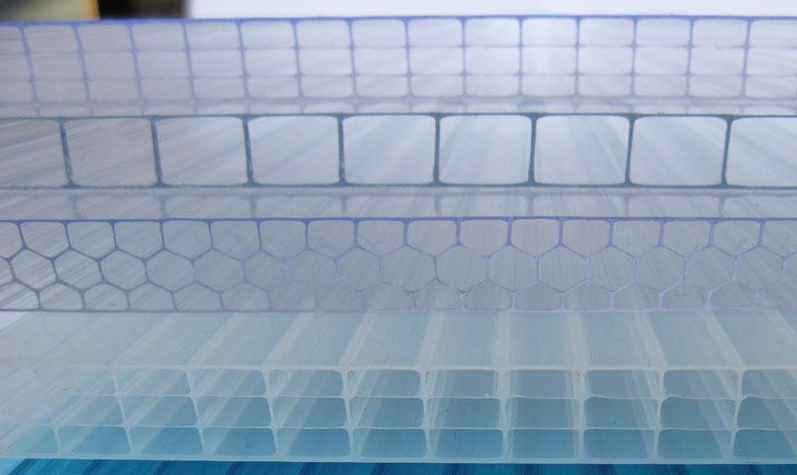

The technology of hollow sheet die

with co-extrusion feed block to get UV+PC+UV, UV+PC hollow sheet can save 30%

UV on the surface.

Application:

PP/PE hollow sheet is light and high strength, moisture-proof, good

environmental protection and re-fabrication performance and can be used into

the reusable container, packing case, clapboard, backing plate and culet.

PC hollow sheet is widely used in construction sunroof in

buildings/halls/shopping center/stadium/public places of entertainment and

public facility; Ring shield of bus station/garages/pergolas/corridors; noise

barriers for highways and urban elevated road

|

PP/PE Hollow Sheet Extrusion |

PC Hollow Sheet Extrusion |

||

|

Extruder model |

SJ-120, SJ-100 |

Extruder model |

SJ-120, SJ-45 |

|

Sheet width |

2100mm, 1220mm |

Sheet width |

2100mm |

|

Sheet thickness |

2-8mm, 2-8mm |

Sheet thickness |

4-40mm |

|

Max capacity |

350kg/h, 200kg/h |

Max capacity |

450kg/h |

|

Main motor power |

132kw |

Main motor power |

132kw |