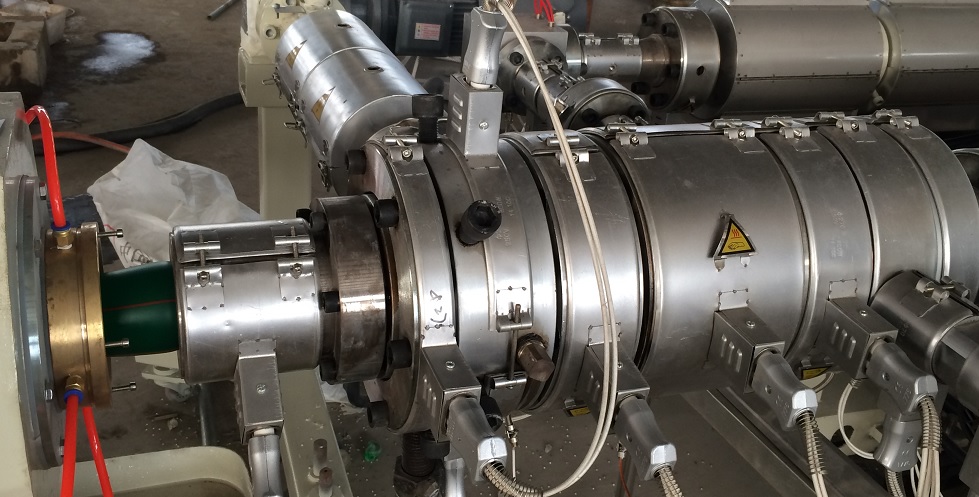

This extrusion line adopts high efficient barrier type

screw, specially designed for PP-R,PERT material, high

quality high speed extrusion, high shear stress and low temperature to ensure

that raw materials can be extruded with high performance. The measurement on

the feeder with the drying system can guarantee the PP-R PERT material

uniformed extrusion.

Split spiral extrusion die head can maintain low melt pressure and low

plasticization temperature. A wide range of polyolefin materials can be

processed by this die head, too.

Vacuum calibrating tank and water spraying cooling tank adopts advanced water

circulation, high pressure cooling system, installed with vacuum degree

adjusting device and automatic water temperature and water level controlling

system. All the pipelines are made of stainless steel to avoid rustiness.

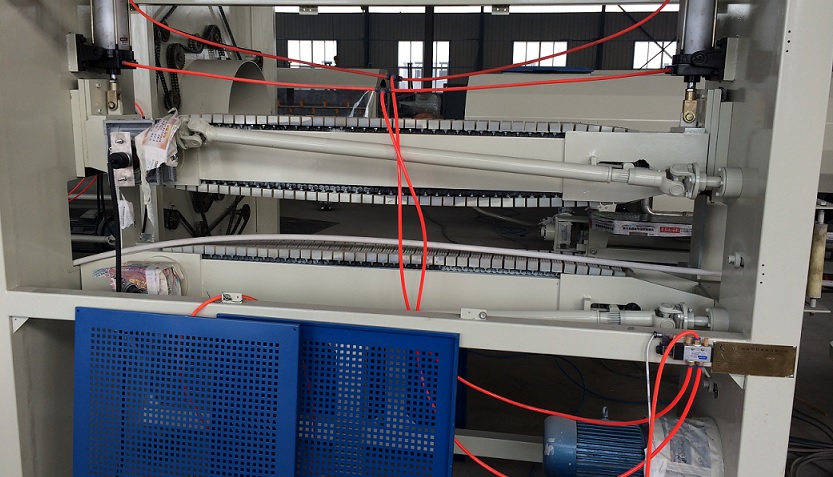

Haul off caterpillars are made of abrasion-resistant material to ensure stable

traction at high speed as well as a long service life.

The automatic non-scraped cutting machine is able to make perfect, non scraped

cuts on the finished pipes. The cutting motion of the saw is controlled by a

synchronous belts drive which operates very quietly.

Pipes produced by this line are widely used in hot/cold water transporting. Pipe

range: 16-63mm, 75-160mm, the maximum line speed can be up to 20m/min.

|

Model/data |

Pipe diameter |

Extruder model |

Co-extruder |

Line speed |

Max capacity |

Installed power |

Dimension |

weight |

|

GES65/30 |

16-63mm |

SJ65/30 |

SJ-25/25 |

1-10m/min |

120kg/h |

55kw |

32*3.0*2.2m |

4.2t |

|

GES90/30 |

75-160mm |

SJ90/30 |

SJ-30/25 |

0.2-4.5m/min |

240kg/h |

120kw |

36*3.1*2.2m |

5.6t |